Offset Printing Plate manufacturers and suppliers

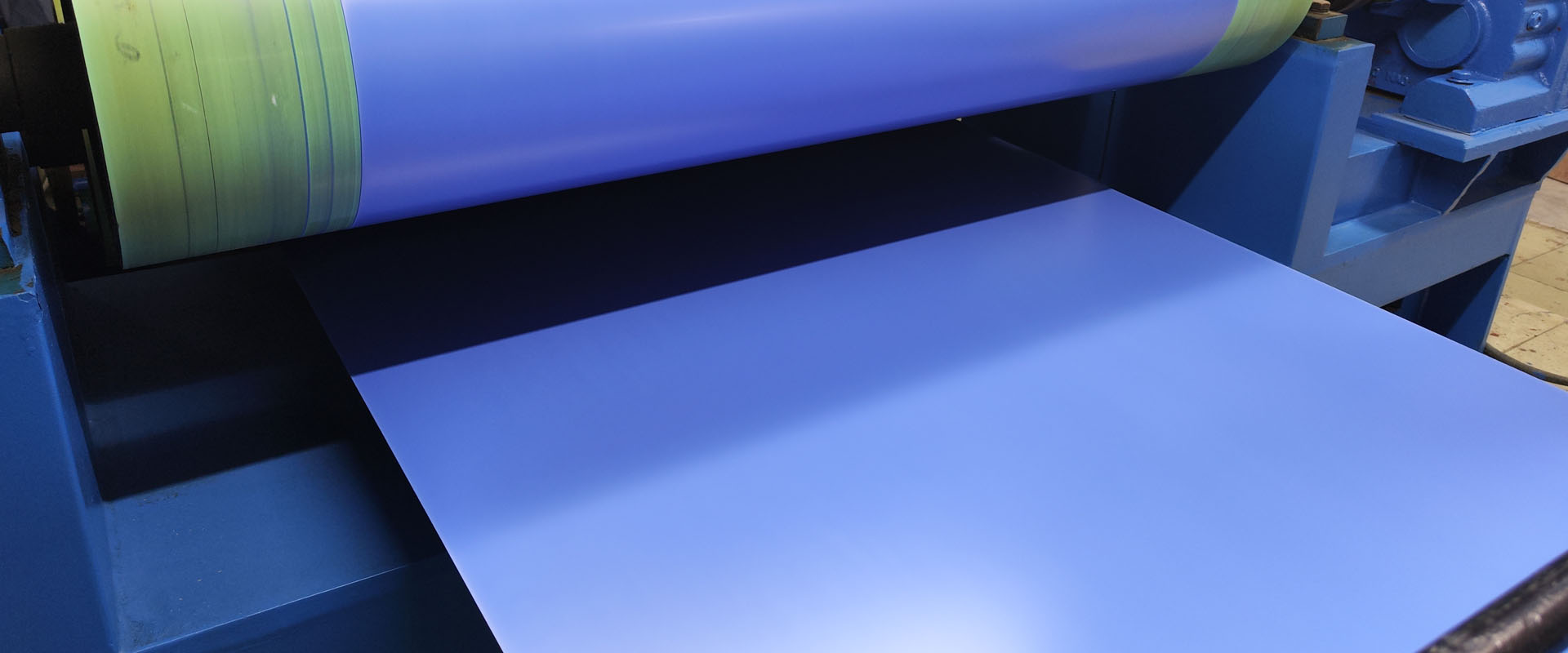

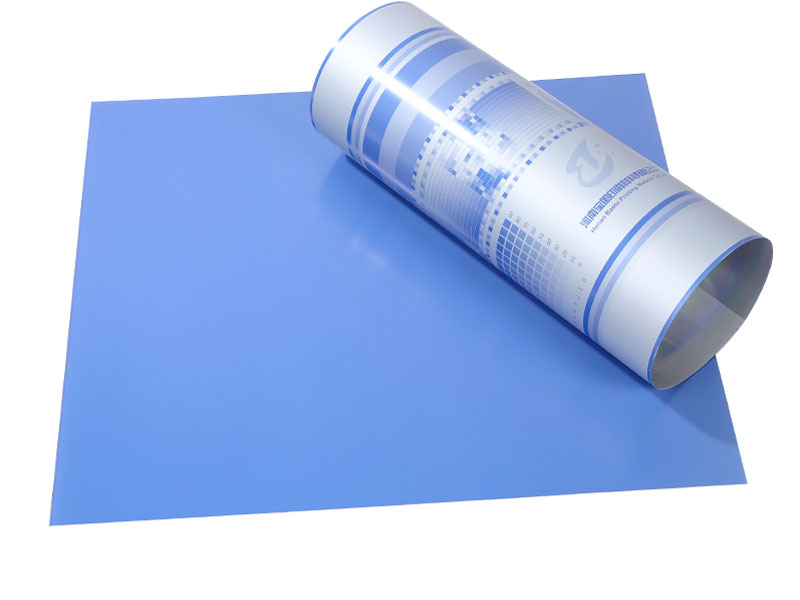

HC aluminium is a high-tech enterprise committed to the R & D, production and sales of new type photosensitive materials. The main products include UV-CTP(CTCP) plate, thermal CTP plate (double layer) and chemical free ctp plate.As an one-stop manufactur in printing industry, we eager for a higher horizon.

The product performance of UV-CTP and temperature-sensitive-CTP has already met international standard, the market share in domestic has reached 8%, and which have been exported to more than a dozen countries in Eastern Europe and ASEAN. Both the manufacture and sale of the enterprise are fine at present for the marketable products and superior quality, and the supply is not adequate to the demand